By the Metal Construction Association

Editor’s Note: This technical bulletin was published by the Metal Construction Association [www.metalconstruction.org], and is republished with permission.

Profiled metal roof or wall panels rely upon mechanical fasteners to secure the components to a structure. It is very important to select the correct type of fastener for metal construction in order to ensure a strong and weather-tight attachment. This Technical Bulletin serves as a guide for the selection of exposed fasteners used with metal roof and wall panels.

Discussion

Fasteners are either primary or secondary in nature. Primary fasteners are used to transfer loads from one design element to another. These loads can be dead, design, imposed and wind loads. Where used externally, these fasteners must provide a weather-tight seal under all load conditions. They are also often required to be coated or colored in some way to match the material they are securing.

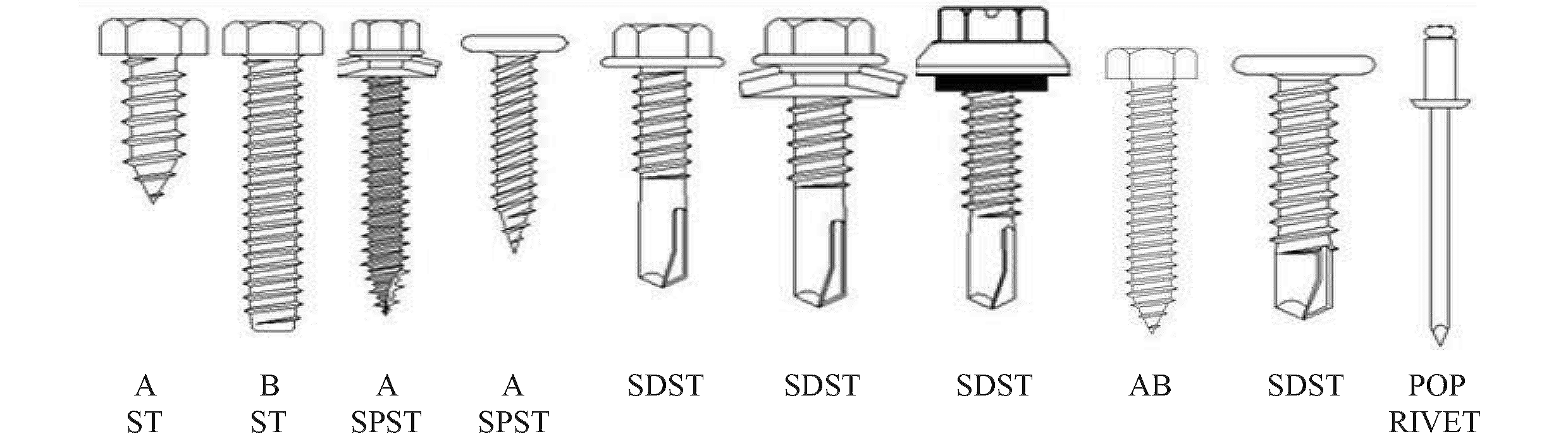

There are many different types of fasteners. These fastener types include “self-drilling,” “self-tapping,” or both. Self-drilling (SD) screws have a drill point in the tip of the fastener. Self-tapping (ST) screws do not have a drill point but are able to tap their own threads into the attachment material. Self-piercing (SP) screws “pierce” through light gauge metals then self-tap (ST) into the material below.

For example, type A, B or AB screws are self-tapping. The fasteners commonly used for attaching to light gage framing are SDST, self-drilling self-tapping screws (SDST). These threaded fasteners have the ability to drill their own hole and form their own internal mating threads. Another type of tapping screw can be “self-piercing,” which has the ability to pierce metallic material 33 mils (0.033”) or less in thickness and tap their own mating threads when driven. Self-piercing tapping screws have a sharp point angle not more than 30 degrees and are often used to secure metal panels to wood substrates.

Secondary fasteners must maintain a secure attachment. They can be used to provide lateral resistance such as part of a diaphragm. They are typically used for stitching of sidewall and roofing laps or securing flashing or other components to sheeting. These types of fasteners are often used with sealants or washers to draw the joint tight. Secondary fasteners may be coated or colored to match the surrounding material. Examples of these types of fasteners may be self-drilling or self-tapping screws, or rivet type products.

Durability

Any type of fastener must be designed to be as durable as the metal wall or roof cladding system itself. Fasteners are available in a variety of substrates and materials with different levels of corrosion resistance and/or durability when exposed to the harsh conditions of weather for years. The metal roof or wall panel manufacturers can provide specific recommendations for selecting fasteners for a specific system.

Compatibility

A potential risk to the integrity and aesthetics of a building exists when the wrong type of fastener is used with a metal roof or wall cladding system. Under certain conditions, premature corrosion of the metal panel and/or the fastener may occur. This effect is known as galvanic corrosion and is often a result of corrosion between the dissimilar metals that are in contact with each other. When selecting fasteners, the relative surface area of the contact points as well as the acidity of the rainfall in the environment need to be considered.

To prevent dissimilar metal corrosion at the connection point, fasteners should be made of the same material as the roof or wall systems whenever possible. At the very least, the fastener should display equivalent corrosion resistance to the material being fastened into. As an example, the use of galvanized steel fasteners with aluminum metal wall cladding systems is not recommended.

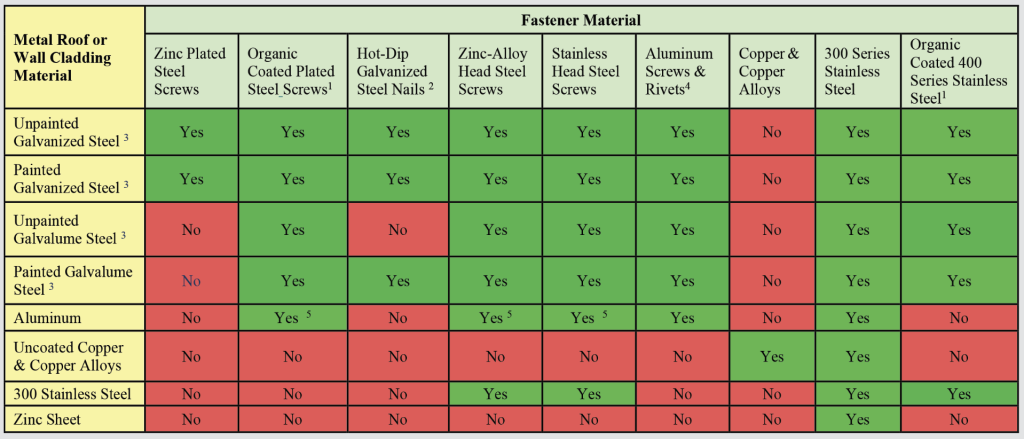

To assist designers and installers with the selection of proper fastener types, the table shown was developed by the Metal Construction Association to serve as a guideline for compatibility with different types of materials. The intent is to show equivalent corrosion resistance between the fasteners and cladding material.

Load Resistance

Fasteners of any type or material are used to resist an applied load. Some connections are critical components in the structural design of the building while others are not. When an attachment involves design critical elements, the use and frequency of any fastening device shall be considered carefully and proven by testing and/or engineering analysis.

SPECIAL NOTE A: Use of Seam Clamps and Brackets

It is common practice to utilize aluminum seam clamps (for standing seam profiles) and specialty brackets (for face-attached profiles) to facilitate the attachment of rooftop ancillaries such as service walkways, solar collectors, snow retention devices and other roof accessories. Seam clamps pinch the seam by some mechanical means, but without penetrating the seam material. In such applications, aluminum clamps are suitable for use with all cladding types tabled with the exception of “Copper and Copper Alloys,” provided that accompanying hardware is 300 series stainless steel. Stainless setscrews or other nodes that engage the cladding material should have rounded tips so as not to abrade metallic coatings on steel, or cause fracture points to other metals listed. Avoid sharp edges or points on fasteners or clamps engaging the seam.

Specialty brackets for use on face-attached cladding profiles when constructed of aluminum are suitable for use with all cladding types in the table with the exception of “Copper and Copper Alloys.” Screws or bolts that attach these brackets should be selected in accordance with the guide table.

SPECIAL NOTE B: Preservative-Treated Lumber Applications

Preservative-treated lumber can be incompatible with certain types of fasteners. In those cases where any type of metal roof or wall cladding materials are being attached to preservative treated lumber, the following fasteners are not compatible: zinc plated screws, zinc-alloy headed screws, stainless capped screws, and aluminum. When attaching metal panels to preservative-treated lumber, a moisture barrier may be used between the lumber and the panel material. Metal panel fasteners that are compatible with preservative-treated lumber are stainless steel fasteners, or hot dip galvanized nails manufactured to ASTM A153 Class D or heavier. Other types of fasteners coated with proprietary anti-corrosive technologies are also available for use with preservative-treated lumber.

• Copper fasteners may be used with preservative treated wood as allowed by code.

• If panels are coated on both sides, a moisture barrier may not be needed.

• Zinc plated fasteners and bolts should not be used with any preservative treated wood. Especially with waterborne treatments.

About the Metal Construction Association

Founded in 1983, the Metal Construction Association brings together the diverse metal construction industry for the purpose of expanding the use of all metals used in construction. MCA promotes the benefits of metal in construction through:

• Technical guidance and product certification.

• Educational and awareness programs.

• Recognition of industry-achievement awards

• Monitoring of industry issues, such as codes and standards.

• Research to develop improved metal construction products.

• Promotional support for the industry.

• Publications to promote use of metal products.

Recommended Fastener Guide

The included table serves as a guideline for the selection of fasteners used with metal roofing and wall panels. The performance of compatible fasteners shown in this table matches the expected life of the metal roof or wall cladding materials. However, in highly corrosive environments such as heavy industrial, coastal marine (within 1,500 feet from a salt water body), high levels of airborne pollutants, preservative-treated lumber or fire-retardant lumber, the compatibility of certain fasteners with metal roofing or wall cladding materials may be affected.

Additionally, corrosive sources on the inside of the building or for buildings where the interior is also exposed to the elements must be taken into consideration when selecting the fasteners. In these types of applications, the manufacturers of the fastener and metal panel will have specific and unique recommendations and should be consulted regarding suitability for use. In addition, in the event that certain coating barriers are damaged or scratched through to the substrate there is increased potential for premature corrosion. Care should be taken during installation and during routine maintenance of the panels in order to protect the integrity of the coatings used for metal panels.

The table shows recommendations based on various cladding material and fastener combinations. Whenever a cladding material is painted, the guidance in the table is based on the assumption that the fastener will also be painted.

Notes:

1. Organic coated fasteners should have corrosion resistance equal to or better than no red rust after 500 hours in ASTM B117 salt spray test.

2. Nails should be galvanized per ASTM A153.

3. The performance of base metal may be impaired by coastal and heavy industrial environments. Consult with the respective manufacturer of any building material or component whenever carbon steel panels and/or carbon steel fasteners are used in coastal and/or heavy industrial environments as these applications may or may not void available product warranties.

4. Commercial availability of threaded aluminum fasteners is very limited due to their lower torsional, tensile, and shear properties. However, aluminum bodied pop-rivets are commercially available and should be used according to the recommended fastener guide. Note that pop-rivets may use different materials for the body and the mandrel.

5. Recommend 300 series stainless steel but manufacturers of the fastener and metal panel should be consulted regarding suitability for use. FBN