By Frame Building News Staff

Wood preservation has a long history in the United States and around the world. The early settlers of the New World in the 17th century used wood preservatives to protect their homes and other buildings.

Significant advances in industrial processing occurred during the Industrial Revolution. Among these advances in the United States was the construction of trans-continental railroads, which created the need for crossties and switch ties. As industrial technology advanced, wood was used more frequently in exterior structural projects. Wood species missing inherent decay resistance properties failed due to biological attack, creating a need for a product that would protect wood.

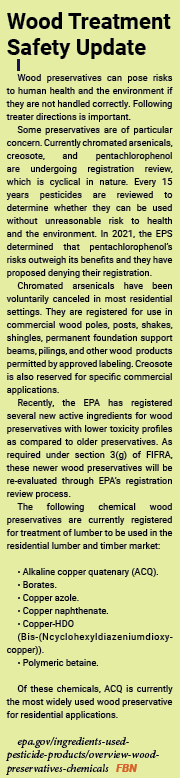

Similar to many industries, the treated wood industry in the United States has evolved as new products emerge, technology advances, and environmental concerns increase. Recently, chromated copper arsenate (CCA) preservative-treated wood has been of concern. A voluntary phase-out of CCA-treated wood for non-industrial uses has increased the attention on new-generation, arsenic-free preservatives.

Choosing Treated Lumber

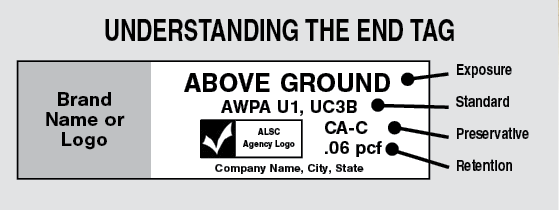

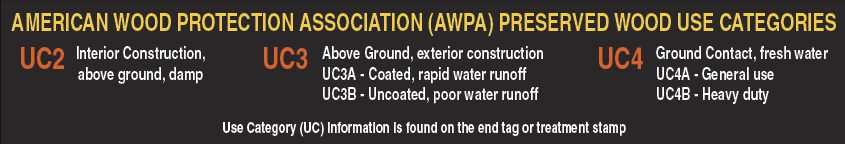

To achieve maximum performance from treated wood, choose material that is appropriate for the conditions in which it will be used. Each piece of treated wood has an end tag that lets you know if the wood is meant for Above Ground, Ground Contact, or Heavy Duty Ground Contact applications. These end use descriptions refer to the conditions the wood is intended to withstand.

Most dimensional lumber is dried in a kiln. Wood does most of its warping, twisting, and cupping as it dries. It’s hard to determine if you’re getting a straight board when it’s still wet.

Treated wood is not dried after treatment. There are exceptions to this, such as foundation grade lumber and plywood, which need to be dried to a moisture content of no more than 19 percent for lumber and 15 percent for plywood. This is referred to as Kiln Dried After Treatment (KDAT). If you are working with other pressure treated wood, allow it to air dry before working with it.

Treated Lumber Codes & Standards

Most architects and engineers specify American Wood Protection Association (AWPA) Standards for treated wood, and they are the only wood treatment standards listed directly in the International Building Code (IBC) and International Residential Code (IRC).

AWPA treated wood standards have been developed over 110 years through an open, consensus-based, American National Standards Institute (ANSI) accredited process to ensure close review of performance data while providing due process for all participants. Many of the world’s experts in wood protection serve on AWPA Technical Committees.

Treating Cut or Damaged Boards

The AWPA Standard M4 requires the use of borates for interior uses and copper naphthenate or oxine copper for primarily exterior uses. For borates, commercial products such as “Bora-Care” may be used, but saturated solutions of borax and/or boric acid in hot water may also be used. “Outlast Q8 Log Oil” is a commercially available oxine copper product which can normally be found at log home supply companies. Copper naphthenate can be hard to find, but it may be stocked at paint, hardware, and building supply stores.

Another method of treating wood is by applying topical liquid treatments. They may contain biocides, insecticides, and pesticides to protect exterior timbers from the elements, insects, and UV light protection.

These treatments are usually applied with a brush or sprayer, with the chemicals soaking into the wood to provide the desired protection to the wood. The main problem with applied treatments is that they only soak part of the way into the wood so the timbers may not have complete protection, especially on the non-treated side.

Treating or sealing cut ends is important with any treated lumber product, however, maintaining a sealed end is most important when using pressure treated lumber in-ground, such as fence posts and landscaping/retaining walls.

Pressure Treated Wood

Pressure treated lumber is insect and rot resistant which makes it a good solution for use in areas that are prone to moisture, for example places where wood comes into contact with concrete or any exterior masonry below grade. Other uses are for decks, boardwalks, landscaping tiles, underwater dock pilings, playgrounds, and poles. However, it is important to note that the pressure treating does not prevent corrosion and weathering and you should, therefore, take other preventive actions as well.

Mold resistant wood is specifically designed to do what it says…resist mold growth and is not a replacement for pressure treated wood. Mold, although unsightly and a potential source of airborne toxins, is not a great threat to wood structure and the soundness of wood members. Mold resistant wood should not be used outdoors or in areas expected to be in contact with soil or masonry such as sill plate because it does not have the insect and rot resistant properties of pressure treated wood.

Fire Retardant Wood

Under AWPA Standards, preservative treatment and fire retardant treatment are two different things. Preservatives are expected to protect the wood from decay, fungi, and termites every day over a long period of time. Fire retardants are expected to remain in the wood and protect it from a one-time event. Some preservatives do impart some fire retardancy, and some fire retardants can act as preservatives to an extent. At this time, there is only one AWPA standardized product which may be used both as a fire retardant and wood preservative, and it is only listed for interior uses. Apart from this, these two types of treated wood should not be used interchangeably.

Treated Wood Fasteners

AWPA’s standards do not supply information regarding corrosion of fasteners and connectors in the field. Therefore, they suggest using fasteners that meet the requirements of the major model building codes, which specify hot dip galvanized steel, stainless steel, silicon bronze, or copper fasteners. The model codes also allow for the use of mild steel fasteners for wood treated with inorganic boron (SBX) in dry environments. There are hundreds of fastener coatings available, so it is important to follow the fastener manufacturers’ recommendations regarding compatibility of their fasteners with pressure treated wood. FBN

• American Wood Protection Association, awpa.com/info/technical/builders

• Simpson Strongtie

• 2018 International Building Code (IBC) https://codes.iccsafe.org/content/IBC2018P2/chapter-23-wood