By APA – The Engineered Wood Association

To ensure optimum performance of engineered wood beams, proper storage and handling practices should always be followed. These recommendations help protect beams from damage during shipment, storage and on the construction site.

Glulam

APA trademarked glulam beams are often protected with wrappings when they leave the mill. But care must be taken during loading, unloading and transporting, as well as in the yard and on the job site.

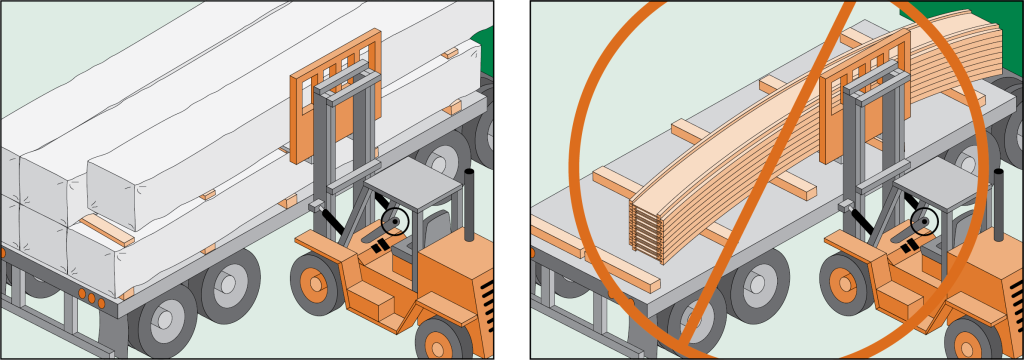

Loading and Transit: Glulam beams are commonly loaded and unloaded with forklifts. For greater stability and handling safety, place beams flat on forks rather than on bottoms (see image at right). Carrying extremely long beams on their sides may cause excessive flexing. Using two or more forklifts, lifting in unison, may help control flex.

A crane with slings or chokers may also be used to load or unload beams, however, it’s recommended to provide adequate blocking at all beam edges between the sling and the members to protect corners and edges. Only fabric slings should be used to lift glulam members. Spreader bars can be used to reduce the likelihood of damage when lifting long beams.

Transport: Stack beams on lumber blocking or skids when loading them on trucks. Beams can rest on their sides or bottoms. Secure the load with straps to keep it from shifting. Protect beam edges with “softeners” or wood blocking when strapping down the load.

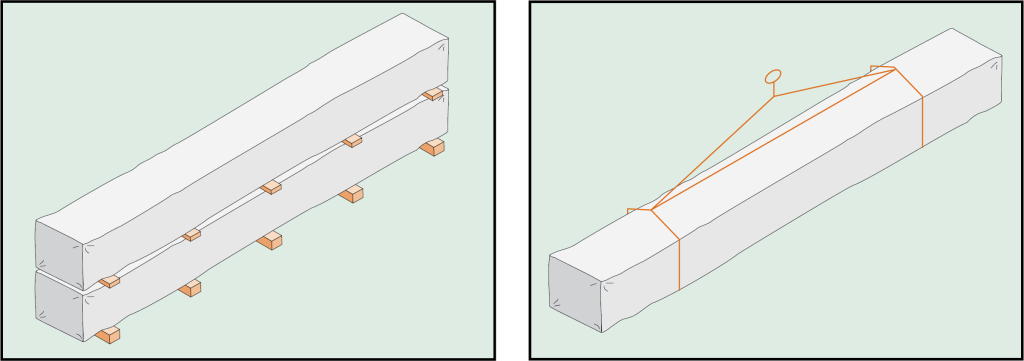

Storage: When possible, store glulam beams under cover to protect them from rain and sunlight. Place beams on lumber blockings, skids or rack systems on level, well-drained ground. Center beams on blockings or racks to evenly distribute the load. Water-resistant wrappings are another way to protect beams from moisture, dirt and scratches.

Because sunlight can discolor beams, opaque wrappings are recommended. Beams can be wrapped individually, by the bundle or by the load. In some instances, the wrappings can be used to protect beams until installation. Sealants on the ends of beams help guard against moisture penetration and checking. The ends of beams should be sealed immediately after trimming.

For long-term storage, cut slits in the bottom of the wrapping to allow ventilation and drainage of any entrapped moisture. Do not expose glulam members to rapid changes in moisture and temperature, such as may occur from temporary heating units.

Structural Composite Lumber (SCL)

Loading and Transit: Care must be taken to protect SCL in all transit periods — from the point where the product is delivered, to job-site handling and storage, to final installation. Take care to avoid forklift damage. If the ground is unlevel in the storage area, reduce forklift speed to avoid “bouncing” the load. When handling with a crane, pick up the load using a spreader if necessary to minimize handling stresses. SCL products are usually shipped in water-resistant wrapping that protects them from moisture, soiling and surface scratches (see Figure 1).

Storage: SCL packages should be set on level, well-drained surfaces, with longest materials on the bottom. Lumber bumpers or blocks should be used to keep SCL packages from direct contact with ground—maintain at least 6-12 inches of ground clearance. For long-term storage, cut slits in the bottom of the wrapping to allow ventilation and drainage of any entrapped moisture to reduce the possibility of water damage, staining or decay. Store SCL in a covered area whenever possible. Maintain stack height within safe limits and do not store other material on top of SCL.

I-Joists

Loading and Transit: I-joists should never be dropped off the delivery truck. It’s recommended to use a forklift with wide forks to handle long length material or use a boom. Never bounce or jerk loads. Maintain low forklift speeds and smooth braking to prevent accidentally dumping. Always keep I-joists vertical when handling and avoid lifting I-joists by top flange. If I-joists are delivered wrapped, don’t open bundles until time of installation (see Figure 2).

Storage: I-joists should always be stacked and stored vertically and level—never flatwise. Maintain at least 12 inches between the ground and the I-joists. I-joists can withstand normal exposure to moisture, but excessive exposure may lead to dimensional changes that affect serviceability. Storing I-joists in a covered area minimizes impacts of weather and moisture. If stored outside, material should be covered to protect from dirt and weather; delay unwrapping bundles until the time of installation. Use stickers to separate bundles, spacing stickers every 8 feet and maintaining vertical alignment.

Have additional questions regarding engineered wood beam storage and handling? Get assistance at www.apawood.org/help. FBN