By Marcus Josiger

Photo Courtesy of Planet Saver Industries.

Post-frame buildings are some of the most versatile structures on the market. Offering a more competitive price as well as a faster completion time, there is little to complain about. However, post-frame does have one trojan horse: moisture. That is why companies like Planet Saver Industries (PSI) dedicate their time to creating solutions for the post-frame world. PSI’s response to moisture and its partner, bacteria, is a simple one: they create a polyethylene dampening system that repels moisture and partner it with a bitumen coating. Before we take a deep dive into this product, we need to take a step back and explore PSI’s beginnings.

Early Beginnings

It was over 20 years ago that PSI began working on Green Post, which is a post-frame product coated with a proprietary blend to extend the product’s life. It was originally inspired by a technique from the UK. Research and development began; machines as well as plastic specifically designed for post-frame had to be developed. Barry Hoffman from PSI remarked, “It was a lot of work, and there were a lot of steps to take before the product was ready to go out.” Universities in both Oregon and Mississippi were tasked to perform accelerated research on the Green Post to ensure it would meet the requirements of the building industry. Despite the time- and resources-consuming process, PSI was on its way to releasing a major product for the post-frame industry. PSI’s driving force for this product’s launch according to Hoffman was, “We just had the right people at the right time.”

Planet Saver’s Objective

PSI’s objective as a company is straightforward: To provide innovation to the post-frame industry. Additionally, it is their goal to extend the life of all wooden products. Not only is it the goal to save clients’ money, but prevent the headache of replacing structures because of rot, too. Lastly, providing a sustainable and environmentally friendly product is a must.

A Look into the Future

Expansion is in sight for PSI according to Barry. “We currently have two facilities open, including the original, here in Pennsylvania, but will be adding four in the near future.” With eyes set on Wisconsin, Indiana, Louisiana, and Florida the sun is shining bright on the company. Additional goals for the organization include expanding its marketing and corporate aspects, and expanding further on the post-frame industry.

Post Work

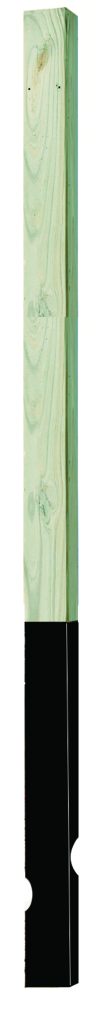

PSI receives its posts from customers only. This gives their clients the opportunity to alter and chemically treat posts to their choosing before PSI handles it. After receiving the order, PSI operators go to work with their machines. The machine requires two operators: one to load and run the machine and the other to unload and inspect posts. Notching is the first step. The patented design removes the need for any on-site alterations such as installing rebar. Following the notch, the product is treated with bitumen and polyethylene. Additional measures are needed before the item is completed. These steps are heating the post to ensure the coatings stay on, as well as rolling the sides of the wood to ensure it is the proper size and fit.

Green Posts’ Features

Green Post deters rot. That is the entire point of the product. But how does it effectively deter rot and what are its benefits? Well, for starters the posts have several notches grooved at the bottom. This is to ensure that when the post slides into the concrete, the concrete has more surface area contact with the post. Essentially it fills in the “gaps.” Furthermore, the bitumen coat, as previously mentioned, covers the very bottom of the post. This is the most critical part of the post because this is where the post contacts the cement or soil. The added value of this applied coating is that it is eco-friendly. It creates a barricade so a treated post will retain the chemicals, and will not seep into the environment.

As an extra precaution, a coating of bitumen, a material has been used for over 1,000 years, is applied. It essentially acts as an elastic wrap that conforms to the post shrinking or swelling. PSI uses this treatment for its entire product range. (The company accepts posts for a variety of uses including mailboxes, fence posts, agriculture structures, and many more.)

The Fight Against Deterioration

To understand PSI’s work, we must recognize how decay develops. Decay initially occurs at the base of where the post is planted. It is from there to about 2 feet down that is most affected by decay. Where moisture, oxygen, and soil come together, you will find bacteria and nearby material will break down providing nutrition for the soil. This process occurs with many naturally sourced items like wood. Concrete, despite not having soil that breaks down, still allows rot. This contributes to posts shrinking during the humid summers. Post shrinkage allows water to funnel into newly formed gaps, allowing moisture-loving bacteria to eat away the wood. FBN