It’s been 25 years since Ken McDonnell conceived of the Post Protector. He was working in the single-family homes residential market, then he took a position as sales manager with a pole frame building company. McDonnell had long admired post-frame construction for its simplicity, speed, strength, and flexibility, but he recognized that the weak link was the posts in direct ground contact. Well, that could be remedied if you wrapped the posts in the right material; he was sure of it!

McDonnell set to work on developing his idea, experimenting with design, materials, and manufacturing processes. It was trial and error. He knew he was on the right track when he introduced an early rendition of the product at an NFBA show. Two gentlemen in suits approached his booth and asked for a product presentation. After McDonnell’s pitch they looked at each other, then McDonnell, and one gentleman said, “You get it!” They were wood scientists from the University of Mississippi, and they became his mentors.

McDonnell kept working on his design using a material prescribed by the Geo-Synthetics Institute at Drexel University, Philadelphia. It is the same material that is used to line landfills, and it boasts a geo-application half-life of 450 years!

McDonnell relates that Post Protector was the first “alternative foundation product” in the post-frame industry; everyone used pressure-treated wood in the ground. Therefore, the first challenge to his fledgling business was encouraging people to try out this new idea.

Understanding the Science

McDonnell soon realized that part of the problem was that most people do not understand how decay occurs or how to stop it. They also don’t understand what pressure treating wood does. So job one became educating people.

“People tend to think decay is caused simply by moisture, but moisture is not the cause but one of the conditions needed for decay to occur. Decay is the action of soil-dwelling decay-fungi /microorganisms feeding on the wood fiber. They feed on dead trees / plants to recycle the nutrients back to the soil to fuel new growth,” McDonnell explains. “These fungi require four things to survive and thrive: oxygen, moisture, temperatures between 40-100 degrees, and a food source (wood).

“In order to stop them in their tracks, you only need to interfere with of one of these four things. That is what pressure treating wood does; it’s a pesticide use to poison the wood fiber to kill feeding fungi. However, chemical protection does not last forever. Once the post is in the ground, the original chemical treatment slowly depletes over time until the wood is again palatable food source for the fungi. At that time decay will commence.”

Over time as people gave the product a chance, word got around that it worked and the company flourished. However, educating people is still job one, according to McDonnell.

Post ProServative

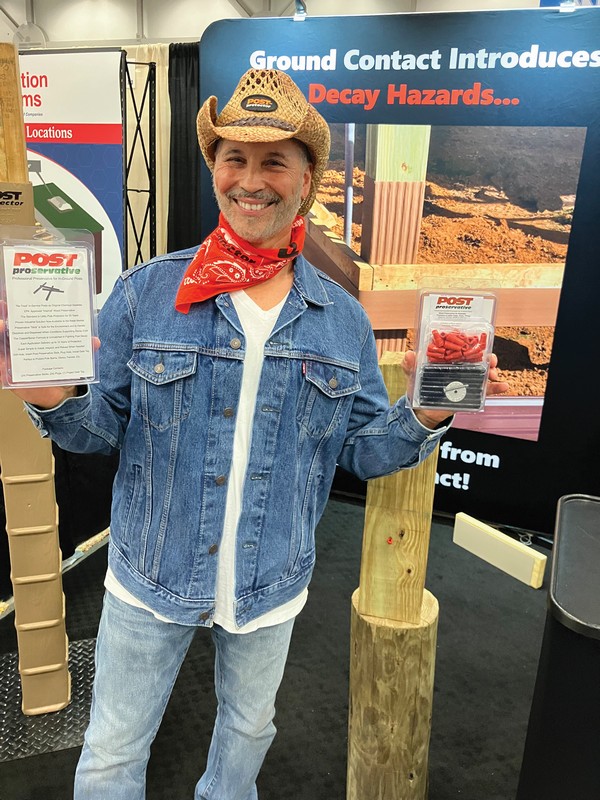

The company has expanded their product line, and the products are used across the U.S. and Canada. They introduced a new product in April of this year, Post ProServative, which is remedial, internal, and reloadable preservative treatment. It’s used to replenish preservative levels to extend the life of those in-service, in-ground posts without Post Protector.

This amazing technology has been only available in the industrial sector, used by utility pole maintenance professionals for over 25 years. Post Protector has the exclusive rights to finally bring it to the retail sector, to maintain barn, fence, and deck posts, for the first time! They are also releasing Post Protector Finish/Sealing caps for 4×4 and 6×6 posts. They provide a finished look and seal out precipitation.

McDonnell worked alone at the beginning, but now he has four employees and an independent sales representative. He has been fortunate in the people he has hired, but he has no advice for companies struggling with this problem; he hired people he knows and friends of friends.

Of course, a positive culture can help, and McDonnell said the company culture is upbeat. They work hard but they also have fun.

“You need to be honest and open and create the kind of atmosphere you would like to work in,” he added.

Carrying Insights Into The Future

“In any industry, the number one key to success is knowing your stuff,” McDonnell said. “Number two: Develop products you are 110% confident in. Then it’s grind, grind, grind. Be relentless.” McDonnell added, “It’s all about excellence in products and service, which is what it says on the (Rural Builder magazine) Gold Key award we were fortunate enough to receive several times over the years.”

Looking forward, he sees a lot of growth to come. He believes that there are a lot of people out there to educate about the benefits his inventions can bring to their post-frame buildings.

“When you consider that years ago, a pole barn was $12,000 to $15,000, and now spending fifty grand on one is easy to do, these are not disposable buildings,” McDonnell said. “Those posts and skirt-board need protection.” FBN

Learn more about Post Protector on its website here.

To read more articles from the January 2024 edition click here.

To read more articles about post-frame post protection click here.