Minimizing Condensation While Keeping Heat In (or Out) of Pole Barns and Houses

Because of condensation, an unprotected, non-insulated pole barn can seem like a tropical rain forest. This is due to the temperature difference created by the outside and inside of it, and the large amount of heat transferred in and out.

You may have experienced the condensation phenomenon when you take a bottle of cold beer out of a refrigerator on a humid summer day and the bottle cools the surrounding air to the dew point; condensation forms on the glass. The dew point is the temperature at which fully saturated air can hold no additional moisture.

Condensation because of moisture (in the form of water vapor in the air) can cause adverse health effects. Also, condensation can cause immediate- and long-term building damage, create critical dampness problems (mold and mildew), and negatively impact building temperature. Condensation is most likely to occur on the inside of exterior walls or roof assemblies, and when there is a high level of humidity inside a building.

Obviously, during hot summer months when the sun is beating down on a roof, heat can penetrate into the building. In the winter, any heat created inside of a building can easily escape. An energy-inefficient building will raise fuel bills, often one of the largest controllable operating expenses. Reflective bubble insulation installed correctly can prevent these problems from happening. It prevents unwanted heat loss (or gain) in structures and keeps internal temperatures within the optimum temperature necessary to avoid condensation.

Additionally, a well-insulated pole barn creates a comfortable space to:

- Service heavy machinery

- Sell products or services to consumers

- Spend quality time with family and friends

- Board, groom, and ride horses

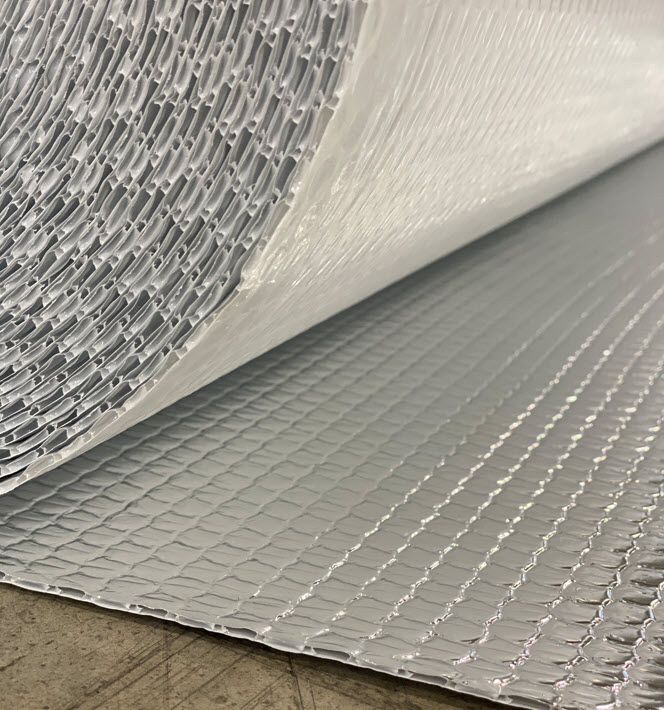

Bubble Insulation

Comprised of air bubbles encapsulated between metal surfaces, bubble insulation can create a radiant barrier that can reflect as much as 96% of the radiant heat from the sun’s rays. Using reflective foils on its surface, it reduces heat transfer and gives a nice clean, finished appearance to the interior of the building.

The bubble foil insulation pack in the center provides a fixed air space and thermal break. It comes in different sized rolls and can be ordered with foil on both sides of it or foil on one side and white on the other. It can be attached to the inside of purlins or draped over them, stapled to rafters or studs, or rolled out onto roof decking or existing shingles prior to installation of metal roofing or siding panels.

Single bubble insulation is very thin and mostly used in warmer climates. It has a highly reflective metalized coating. It’s durable, yet easy to cut with utility knife or scissors, and is lightweight, and easy to handle and install. Most have a 1/8” approximate thickness, which compresses slightly while on the roll.

Double bubble foil insulation features an extra layer of bubbles to provide maximum protection against condensation build-up in colder temperatures. Two layers of bubbles help prevent formation of frost and condensation on either side of the material. It acts as a 100% vapor barrier when properly installed with insulation tape. Both types of this bubble insulation can be a barrier for methane, radon, moisture, termites, and other pests. They can be combined with fiberglass or foam insulation, or on their own; always refer to local building codes.

“Single bubble and double bubble can both be made with white/foil or foil/foil applications,” said Jake Jeppeson, east manager, MWI Components. “White/foil has white on one side with one layer of metalized, low-emissivity surface on the other. Foil/foil has two layers of metalized, low-emissivity surface on both sides of the bubble.

“Single bubble can be used in tighter spaces than double bubble. Double bubble has more structural strength and rigidity than single bubble. White/foil’s metalized surface on one side of the bubble reflects radiant heat away from the structure while providing an opaque finish on the inside. Foil/foil’s metalized surface on both sides of the bubble reflects radiant heat away from the structure and helps maintain a comfortable temperature on the inside due to the added metalized layer.”

“These products are designed for new and retrofit installation in roof and wall assemblies of post frame buildings,” said Wesly Hall, sales manager at Reflectix. “The products provide a range of R-values depending on where and how they are installed in the building.”

“The key to the product is not the bubble, it’s the foil,” said Kelly Myers, national sales manager at rFOIL Insulation Products. “The foil is doing all the thermal work; the foil is a fantastic insulator. Metal gets heated up — superheated by the sun — then it turns into a giant radiator. The foil takes that heat radiated off the hot metal, then bounces it back in the direction it came from. The result is it slashes the heat gain inside the building.”

Installing Reflective Bubble Insulation

To achieve the maximum performance, the insulation must always be properly installed according to the manufacturer’s specifications. But Myers said installation isn’t problematic. “It is really simple. For anyone who knows how to install installation of any kind, this is as easy as it gets. [Bubble insulation usually] runs parallel to the metal usually stapled to the purlins, or laid down on the purlins and tacked down on the purlins with nails. Ideally you will tape the seams where two [rolls] come together. Ideally, if you can get a little bit of a drape between the purlins that’s great.”

Hall agreed with this ease of installation. “It is a very straight forward installation and only requires basic hand tools. [It involves] fastening with staples or screws, to the framing members of the structure. There are no typical problems related to installations. One of the benefits of installing a reflective insulation is the ‘easy to handle and install’ characteristic of the product. This feature reduces the labor necessary for installation and provides an ‘itch-free’ product experience.”

To function correctly, according to Ron Holder, general manager at Bay Insulation Systems, it should always be installed with the reflective side of the product facing an airspace. “This airspace can be quite small — ¾” for the product to be effective. Caution should be taken to ensure the products installed have been properly tested to ASTM and to RIMA Standards. Untested products may not have the correct inhibitors added in. Exterior applications where it is exposed directly to the elements should be avoided. Caution should be used around electricity. Avoid temperatures over 180F.”

Innovative Energy’s AstroShield and Astro Armour reflective insulation products can be installed in metal and post frame buildings with a ¾” air space on each side of the insulation for optimal performance. “The air space may be larger, but a smaller air space can affect the performance of the material. To create a vapor barrier, the seams of the material should be butted and taped with either foil tape or white poly tape,” said Whitney Hagarbome, vice president at Innovative Energy Inc. “All seams must be sealed thoroughly to create a vapor barrier.

“Never use duct tape on either material. Both materials should be installed at least 3’ from any heat-producing fixtures, chimneys, blowers, etc., and never install either AstroShield or Astro Armour directly above lighting or other heat-producing devices because metalized film is an excellent conductor of electricity.”

Jeppeson said, “Gaps between rolls may allow air to penetrate, reducing the effectiveness of the insulation and increasing the risk of condensation buildup. Ensure complete coverage of material when insulating by overlapping and taping seams. [To ensure the requisite] ¾” air gap between the barrier and the surface exposed to the heat source to reflect radiant heat most effectively … install furring strips between the radiant barrier and the installed surface.” FBN

Reflective Foam Insulation

By Tim Easley, CEO, Dutch Tech Inc.

Single and double bubble have been around for many years. They got a bad wrap from the start because their product fell apart shortly after being on buildings. A newer product to the market is reflective foam wrap. Its woven, tarp-like backing holds in place to framing much better and has raw materials that will likely last beyond its 10-year warranty.

Reflective foam insulation like Therma Guard has a strong and durable woven backing that does not disintegrate over time. Its reflective nature does not absorb or retain heat. It was designed to be easy to install with standard staples, no special tools needed. It can be used as an air and/or vapor moisture barrier, and keeps the interior cool in hot summer months while keeping interior heat from escaping in cold winter months. As with all insulation it improves the energy efficiency of buildings. And, it can also help to deaden sound of weather when installed on a roof.

Reflective Bubble Installation Guide

By Jake Jeppeson, East Manager, MWI Components

New Construction

Roof Application. Staple the foil insulation by running the foil insulation across the trusses. Purlins should be installed over the insulation. The purlin will create an airspace between the foil insulation and the roofing steel.

Wall Application. Staple the foil insulation horizontally to the support beams. Horizontal girts and sidewall sheet steel can be installed over the foil insulation. From the interior, the foil can be stapled to the horizontal girts.

Frame Retrofit

Retrofit Roof Application. Staple the foil insulation to the bottom of purlins and the bottom of the top plate at the walls. Tape butt seams with foil tape. When applying new sheet steel on a retrofit, the process for new construction can be followed.

Wall Application. Can be installed either horizontally using the girts or vertically by installing furring strips on the interior of the building.

Reflective Bubble Insulation Resources

Bay Insulation

Green Bay, Wisconsin

(920) 406-4200

www.bayinsulation.com

Dutch Tech, Inc.

Lobelville, Tennessee

(931) 325-0000

www.dutchtechindustries.com

EcoFoil

Urbana, Iowa

(888) 349-3645

www.ecofoil.com

Fi-Foil Company

Auburndale, Florida

(800) 448-3401

www.fifoil.com

Innovative Energy Inc.

Lowell, Indiana

(219) 696-3639

www.innovativeenergy.com

Insulation4Less

Houston, Texas

(281) 369-4831

www.insulation4less.com

Johns Manville

Denver, Colorado

(303) 978-2350

www.jm.com

MWI Components

Spencer, Iowa

(800) 360-6467

www.mwicomponents.com

Plyco

Elkhart Lake, Wisconsin

(800) 558-5895

www.plyco.com

rFOIL Insulation Products

Shawnee, Kansas

(800) 837-8961

www.rfoil.com

Reflectix Inc.

Markleville, Indiana

(765) 533-4332

www.reflectixinc.com

US Energy Products

Miami, Florida

(786) 317-8844

www.usenergyproducts.com

This article is from the November 2023 edition. Click here to read more articles from that magazine.