According to the National Association of Home Builders, about 75% of residential home builders use prefabricated roof trusses. There are several advantages to using prefabricated trusses, but the main advantages include time saved by installing them rather than building rafters onsite, lowered cost, and the pre-engineering that goes into a prefab truss to withstand the loads required of them. Components built onsite are not standardized in the same manner. Saving time, money, and dispelling any concerns regarding the ability of the trusses to perform as planned are great incentives for builders to use prefabricated trusses.

The Strength of Trusses

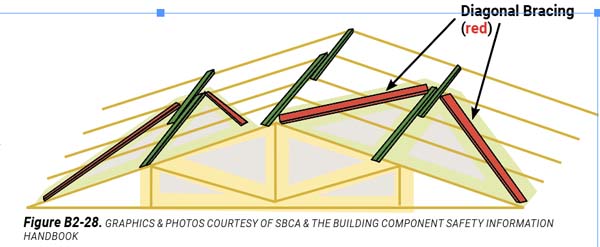

Trusses are engineered to support the roof and any wind or snow loads the roof may be expected to experience. The truss is built based on triangles because triangles are one of the strongest shapes, and any load can be transferred between the three sides. In a truss, the design distributes the load over the entire truss, transferring some of the load to the frame, while weighing less than a solid slab would. Trusses are constructed of wood or metal. Wood is often used for smaller buildings, but as the spans grow longer, as in riding arenas and larger pole buildings, a metal truss is called for.

Parts of a Truss

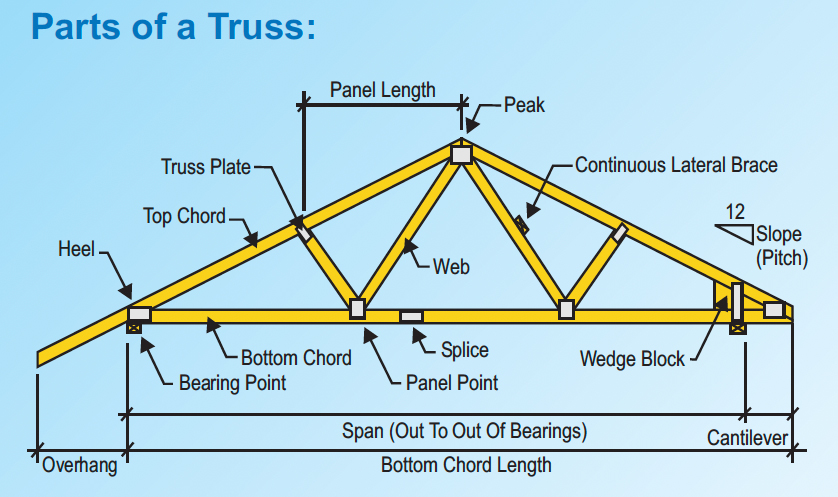

It is easier to discuss trusses when you know the names of the various parts. The top chord spans the length of the truss, while the bottom chord stretches across the bottom. The two are attached by “webs.” These are, often, triangles within triangles, so the strength and load transference is enhanced.

The heels are where the top and bottom chords come together and the point at the top is the peak. See the diagram below for further details.

When considering a truss, the bottom chord without any overhang is the “span.”

Truss Types

There are a variety of truss configurations that may be used. The specific design will vary depending on applications, building materials and geographic and climactic conditions. The type of truss chosen may also be impacted by roofing configurations that are part of the plan.

Let’s begin with the basics.

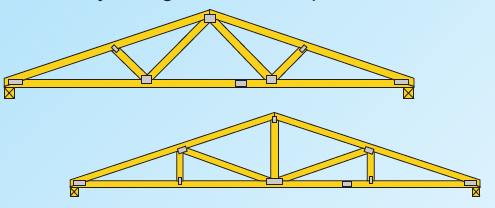

Common Trusses (or Pitched Trusses) –

These are, as the name suggests, some of the most-used trusses. Their distinguishing features are their triangular shape with the same pitch leading to a heel on each side. Common Trusses are used for the most common roof shapes.

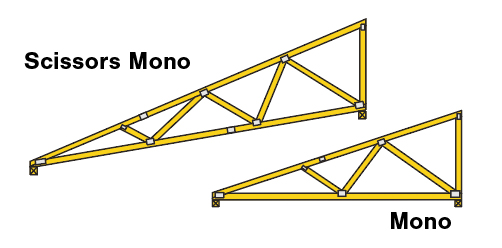

Mono Trusses –

These trusses are used when the roof slopes in one direction only.

Scissors Trusses –

Use of these trusses creates a cathedral or vaulted ceiling

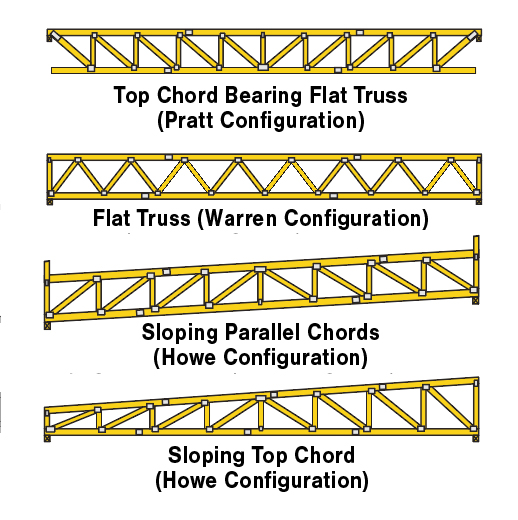

Flat Trusses –

A flat roof calls for a flat truss.

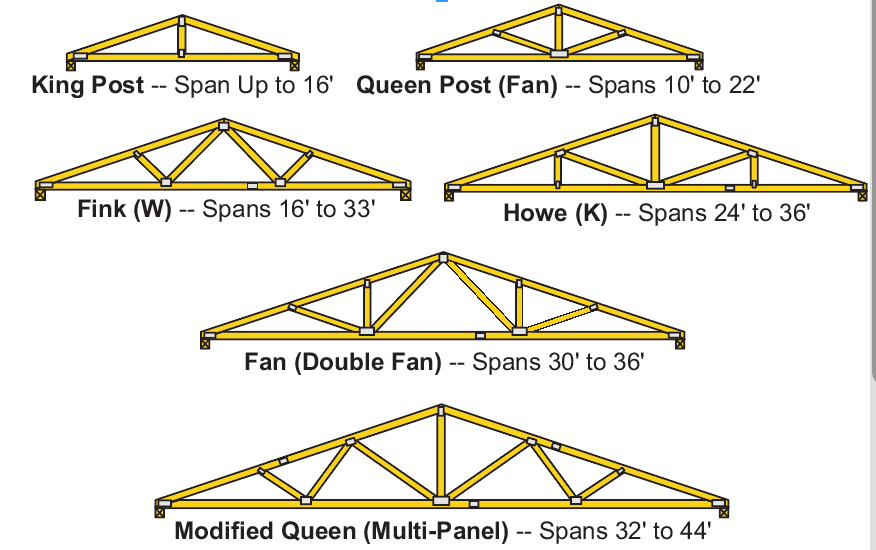

Common Truss Configurations:

King.

A simple triangle with a post in the center, the king’s strength is in its simplicity. It is easily created and assembled and few errors accrue to this truss type. Further, an engineer’s software will have little difficulty analyzing the strength and efficacy of a king truss.

Queen or Fan.

The queen is much like the king with extra bracing, so it can be used for longer spans. Naturally, the additional members and longer span add up to additional cost.

Fink or W.

Fink trusses provide greater strength than a queen and can span 30 meters. It boasts an efficient use of materials with its W-shaped, uncomplicated design.

Fan or Double Fan.

Characterized by its radiating fan shape, the Fan Truss is used for spans that can’t be accommodated by a king or queen.

Modified Queen.

A queen truss with its extra members is composed of 8 triangles with a central post and 3 web members on each side. They can be used to support a variety of roof types.

Howe or K.

The upright post members combined with diagonal members can support up to a 200-foot span.

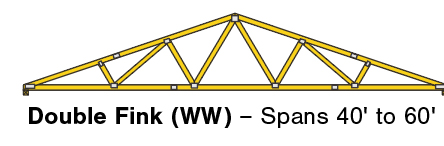

Double Fink or WW.

As the Fink web forms a W, so the Double Fink forms two Ws. Generally this configuration is used for larger buildings, as for example warehouses and industrial buildings, but they may also be used in residential.

Double Howe or KK.

With 5 vertical posts, the Double Howe trusses are made to support a lot of weight. They are typically used in bridge construction or other places where great loads will be incurred.

Modified Fan or Triple Fan.

Lighter than a Double Howe, the modified fan is a more economically desirable choice, but it cannot bear the load of a Double Howe.

Triple Fink.

This truss is made up of thirteen triangles sloped at different angles, making it capable of holding a lot of weight while remaining lightweight.

Triple Howe.

With 5 vertical posts and 6 diagonal posts, the triple howe is more rigid than other howe trusses. It is often used in warehouses and factories.

Gable.

These trusses create the short triangular ends of a building. The many vertical posts help transfer vertical loads.

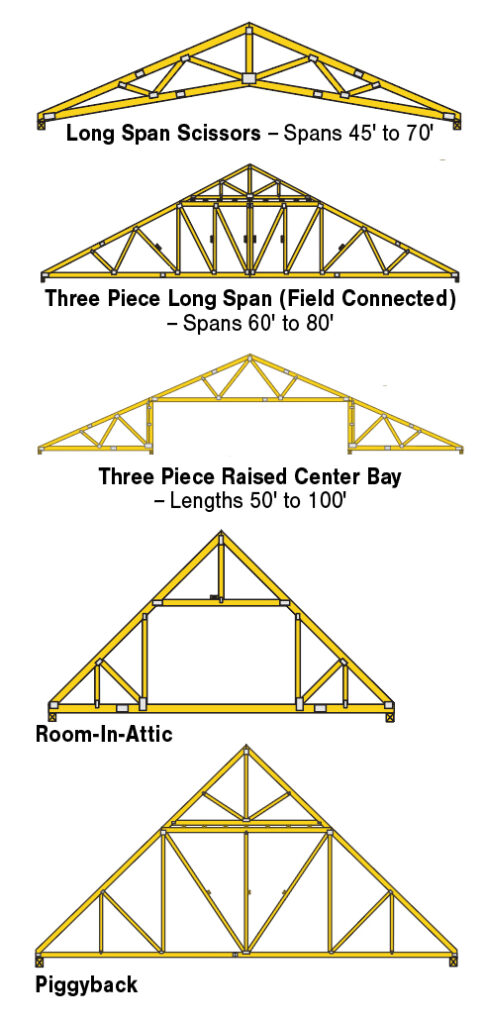

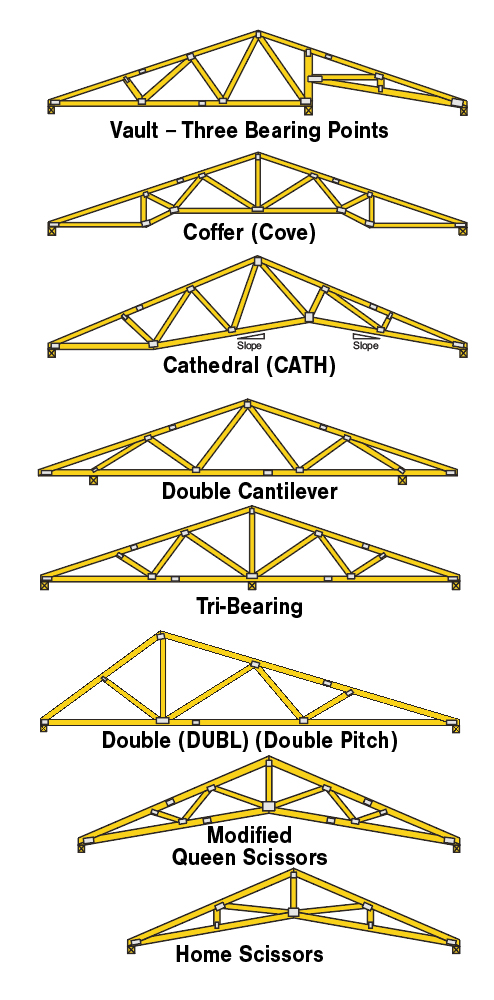

For Vaulted and Cathedral Ceilings

Vault with Three Bearing Points.

These truss types are used to vault the ceiling. They have a third load bearing point to help with the load. Typical spans are 24’ to 60’.

Coffer or Cove, Cathedral and Modified Queen and Scissors Trusses.

They come in a variety of sizes and all are varieties of scissors trusses generally used to create extra room for a cathedral or vaulted ceiling.

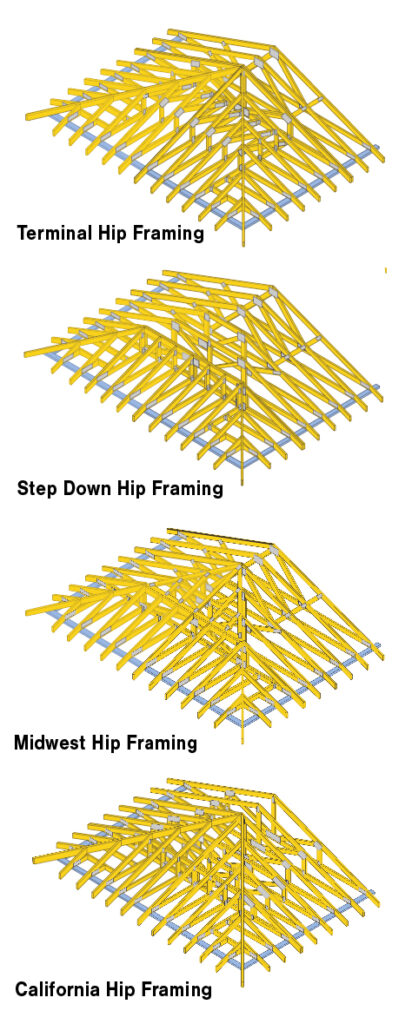

Hip Framing.

These trusses usually come in sets that are used to create hip roofs. A hip roof consists of four sloping panes that meet at the top. This system is self bracing and creates a very strong roof. Terminal hip trusses are generally useful for shorter spans, 26 feet or less. Step Down hip framing is used for longer spans and is considered the most versatile. Midwest Hip framing is also for spans over 26’ and creates a more uniform structure to attach roof decking. The California hip framing system is an alternative to the Step Down, but is better with shorter slopes.

Room-in-Attic.

When a customer wants room in the roof, this truss frames it for you.

Piggyback Trusses.

This is actually two smaller trusses that can be separated for shipping.

Flat Trusses.

Flat trusses can be used for flat roofs or roofs with low pitches, but they are also used at times to create cathedral ceilings.

How Does One Decide on a Truss Configuration?

This brief list includes the main considerations when choosing trusses:

• The load and stress the truss must bear

• The span required

• Building codes

• The budget

• The design and shape of the roof

Thank You to Our Truss Experts:

• Buffalo River Truss, LLC www.buffalorivertruss.com

• Graber Post Buildings, Inc. www.graberpost.com

• Capital Truss & Lumber www.capitaltruss.com

FBN