Metal has long been a powerhouse in construction, but recent innovations in metal finishes have propelled its popularity to new heights. Advances such as 3D metal printing, high-tech coatings that replicate wood and other materials, and new profiles like metal board and batten, lap siding panels, and even metal that mimics 3D logs have expanded its appeal among specifiers and building owners. A recent online survey conducted by Shield Wall Media confirms this growth, with more than 90% of respondents reporting an increase in metal’s popularity. As its use expands into new applications, let’s explore the finishes, coatings, profiles, and equipment driving this trend.

Advancements In Finishes

In recent years, coil coating technology has leapt forward, driven by innovations that transform both the aesthetics and performance of metal construction components. Steel Dynamics’ 3D printing and AkzoNobel’s coating systems are representative of the next frontier in coil finishing technology—merging aesthetic excellence with robust performance. Let’s take a look at why these innovations are pivotal in driving the future of building with metal.

3D printing on metal has revolutionized the industry by enabling designers to create custom shapes and intricate details that were previously impossible or prohibitively expensive. This innovation results in lighter, stronger, and more efficient metal components that meet unique architectural needs while minimizing material waste—benefiting both sustainability and creative design.

Steel Dynamics’ (SDI; www.steeldynamics.com) Tru>Steel HD® specialty coil has significantly impacted metal’s use. Introduced in 2022 after two and a half years of development, Tru>Steel HD® convincingly replicates the appearance of wood and camouflage. SDI’s proprietary system utilizes high-tech 3D scans of actual materials to create authentic images that are printed on metal with a resolution up to 400 dpi. The collection includes, but is not limited to, striking patterns such as Cedar, Rough Sawn Cedar Dark Brown, Barnwood Plank, Pecky Cypress, and Charred Wood.

Conrad Farley, National Sales Manager at United Steel Supply [https://unitedsteelsupply.com]—SDI’s distributor for Tru>Steel HD®—explains the difference between traditional print roll patterns and hyper-realistic Tru>Steel HD®: “Standard prints have a repeating roll pattern every two to three feet. Tru>Steel HD®, on the other hand, uses real imaging.” To achieve this, the development team photographed 400 square feet of material, producing a 32-foot-long image. Real materials are replicated in all the patterns; natural elements were gathered and scanned to create an unbroken, realistic print. “That’s the difference in quality,” says Farley. “Once installed, it looks so real you have to touch it to know it’s steel.”

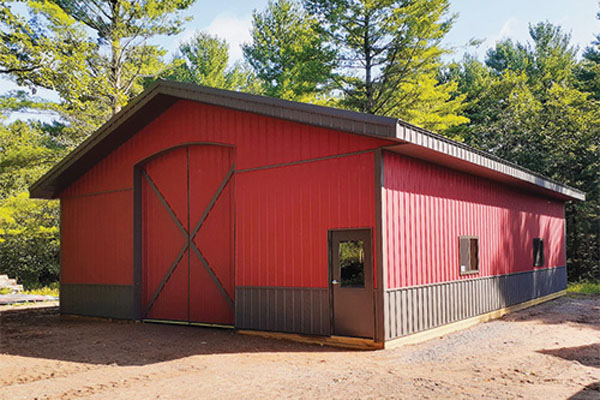

Recognizing the demand for natural-looking finishes, Graber Post Buildings [www.graberpost.com] collaborated with SDI to select the best images for the board and batten profile. As the first Tru>Steel HD® customer, Graber Post initially ordered a small quantity of the digitally printed product, which sold out quickly. Today, they are one of the largest Tru>Steel HD® outlets, stocking a variety of wood-grain prints, including Hickory Natural, Rough Cedar Natural, Rough Cedar Aged, and Rough Cedar Natural. These prints are available on board and batten, standing seam, trim components, and in coil form.

Beyond prints, flat and textured coatings also help disguise metal, eliminating the shine and softening its appearance to better mimic wood and stone. However, formulation is key. AkzoNobel’s CERAM-A-STAR® Expressions is a high-performance silicone-modified polyester (SMP) textured coating that enhances wood and stone prints. Developed with the advanced CERAM-A-STAR® 1050 platform, this coating uses proprietary resins and additives to deliver excellent durability, moisture and UV resistance, flexibility, and abrasion resistance. AkzoNobel’s [www.akzonobel.com] Amanda Paterline says, “The natural-looking wood, slate, or granite finishes make it a versatile choice for lap siding and board and batten applications.”

For siding applications, Paterline advises considering the full pre-painted metal system to ensure optimal performance. CERAM-A-STAR® Expressions comes with a best-in-class 40-year warranty for film integrity and performs best on properly cleaned and pretreated aluminum, Galvalume, and hot-dipped galvanized substrates. Additionally, special consideration is needed for coatings applied to embossed steel. AkzoNobel’s POLYDURE® portfolio offers solutions tailored to various fabrication processes, ensuring maximum flexibility and durability during forming, bending, and embossing.

CERAM-A-STAR® Expressions is a high-performance silicone-modified polyester (SMP) textured coating that enhances wood and stone prints. Courtesy of AkzoNobel

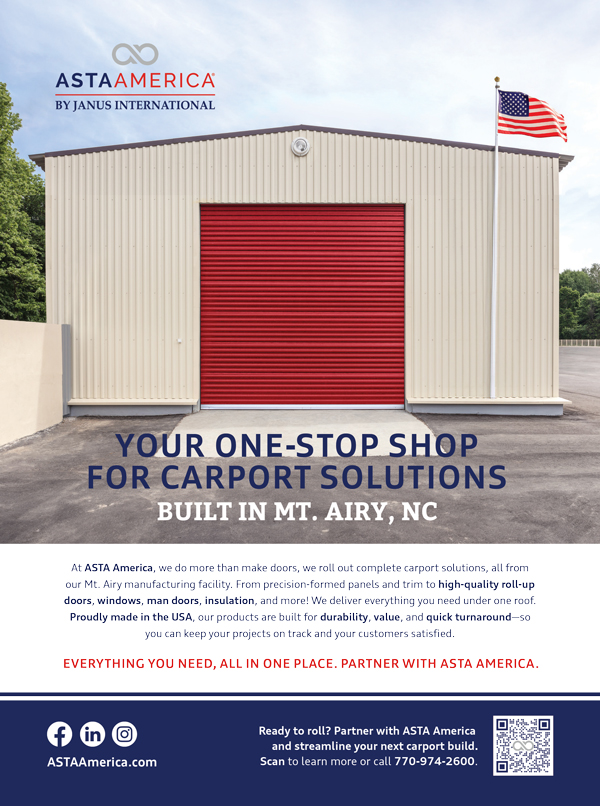

Forms and finishes look so convincing that you need to touch this siding to know it’s not wood. Courtesy of Steel Dynamics Inc.

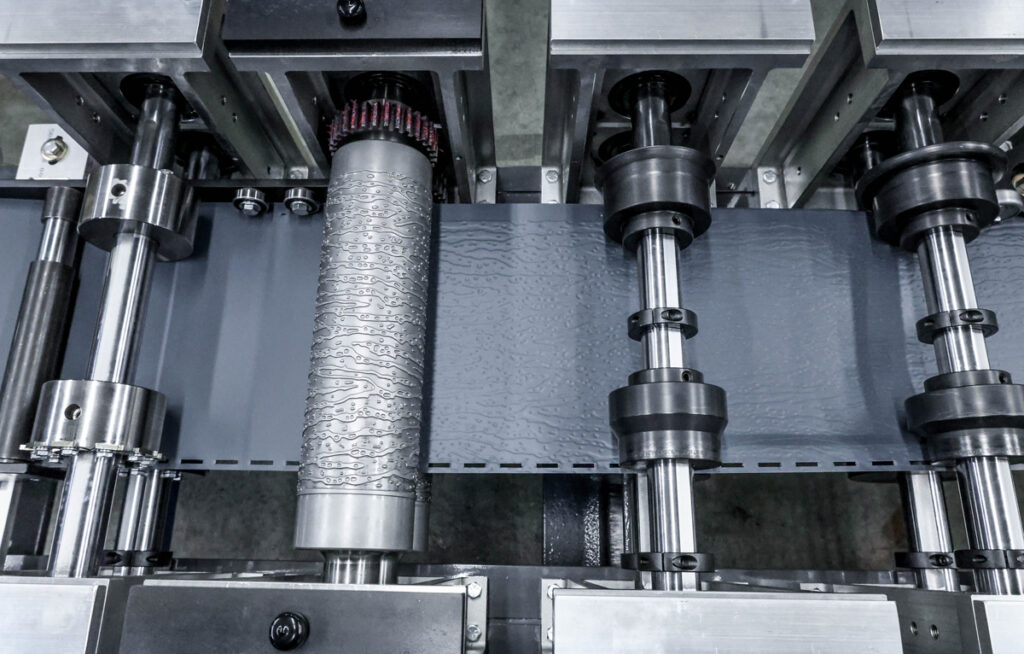

Coil going through the woodgrain embossing process of an Eastside Machine Co. machine. Photo courtesy of Eastside Machine Co.

Is the siding wood or steel? Courtesy of Steel Dynamics Inc.

Metal Siding: A Modern Take on Classic Forms

Board and batten, lap siding, Dutch lap, and even rustic log siding can now be replicated in metal.

Traditional wood board and batten siding, a staple in the residential market, is losing ground to metal board and batten. Metal provides the same charming aesthetic but with added durability, fire resistance, and low maintenance. When New Tech Machinery [www.newtechmachinery.com] introduced a portable roll former capable of producing board and batten profiles, it quickly gained popularity. “Our SSQ II machine can create panels designed to look like wood, stone, or vegetation—whatever is on the paint-coated metal,” explains Rick Zand of New Tech. “The industry is becoming more creative, allowing customers to bring a design to a metal manufacturer and have it replicated on the coil.”

Farley emphasizes the appeal of metal siding profiles: “There’s a lot of new equipment coming out, and costs are decreasing. Aluminum, vinyl, or wood board and batten require extensive maintenance, but steel is maintenance-free—no need to restain, repaint, or worry about moisture damage.” As a result, metal board and batten is becoming a top choice for homeowners and builders alike.

Graber Post has found great success with its board and batten profile, which offers the timeless look of traditional siding without the upkeep. By utilizing Tru>Steel HD® and AkzoNobel finishes, Graber Post has provided a durable, visually appealing alternative to conventional wood siding.

Lap siding has also been a popular choice for residential and commercial projects. Now, metal lap siding panels offer a sleek, modern alternative to fiber cement or vinyl. These panels are highly durable, weather-resistant, and suitable for various architectural styles, from traditional to minimalist.

Metal Rollforming Systems [https://mrsrollform.com] offers numerous profiles designed to mimic wood, including board and batten, lap siding, soffit/horizontal cladding, and raised panels. Many options come in through-fastened or concealed fastener panels, providing flexibility in pricing and inventory management.

Many equipment manufacturers gauge the amount of interest in a panel profile to determine new machine development/offerings by paying attention to customer feedback, market trends, surveys, and testing new innovations in the field. “Our role tends to be a collaborative one,” says Bill Griffin, Metal Rollforming Systems. “We’re fortunate to have amazing customers and industry relations both on a national and international scale, this allows us the ability to be at the forefront of innovation. By aggregating these market trends, and collaborating with customers in a one-on-one environment, we’re able to bring new and exciting designs to market. Consideration is given to coil widths and gauges, by designing around industry standards we are able to provide a cost effective solution to our customers without the need to add additional inventory, reducing costs and increasing inventory turns.”

New Tech Machinery takes product development very seriously, as well. “New Tech is always looking to innovate with features based on customer feedback,” says Zand. “We strive to be the premier manufacturer of portable roll formers and industry leaders when it comes to servicing, training, innovation, and technology.”

Eastside Machine Company’s [www.eastsidemachine.com] Brad Olson says, “We are always developing new profiles based on customers’ needs as they come to us. We ask them to send us the profile they would like to see, and we will build the attachment to make it. There is virtually no limit to what we can create. In ninety percent of the requests we receive, we are trying to mimic a wood product from the last 150 years. Every trend goes in cycles. For example, we’ve had our board and batten profile since the ‘70s, and it has recently begun experiencing a resurgence in popularity. … Most recently, our plank profile, which resembles shiplap, has experienced significant attention.”

Eastside Machine Co. has a long history in roll forming. In 1973, the company patented a machine capable of producing 8-inch lap siding from aluminum coil. In fact, it was the first to successfully manufacture a portable siding machine with embossing, which was patented in 1977.

The Road Ahead

These innovations have transformed metal’s role in construction. No longer limited to industrial applications, metal has become one of the most versatile, stylish, and practical materials for homes and commercial buildings. Specifiers appreciate its ability to balance design and performance, while building owners benefit from its longevity, low maintenance, and cost-effectiveness.

“Architects, builders, and homeowners have long loved the look of wood, but the maintenance has always been a drawback,” says Griffin. “New profiles, coupled with advanced coatings and printing options, offer wood alternatives with significantly longer lifespans and reduced upkeep costs.”

Farley underscores the significance of these developments: “Board and batten and shiplap were not available in steel until recently. Now, they’re game-changers for light-gauge construction, opening up a whole new market for metal.”

Griffin agrees: “The collaboration between equipment manufacturers, coil suppliers, and coaters has propelled our industry forward. With manufacturers’ lead times extending beyond six months, staying informed and planning ahead is crucial.”

The bottom line: metal is no longer just about function—it’s about aesthetics, too. Thanks to these advancements, it’s becoming the go-to material for projects for which metal would not have been considered not long ago.

Applied Films Warm The Look of Metal

By Continental Surface Solutions

“Outdoor metal surfaces in buildings don’t always fit the desired aesthetic of the build. One solution to disguise the metal is using films to cover the surface.” – Joshua Snyder, Head of Industries – Exterior Surface Solutions, Continental.

Outdoor films like the ones Continental Surface Solutions creates can be used to cover metal surfaces so they look like anything else – from various wood decors to matte surface textures in stylish colors. They can be used on window frames, doors, garage doors and facades. These films are mechanically laminated, easy to clean and long lasting, which cuts down on maintenance costs. Continental actually does extensive time-lapse weather simulations to make sure these films hold up in the most destructive types of weather.

Many builders are looking to mimic the outdoor environment in their builds, and exterior films can do that. A builder might use a pine-colored film to cover the window frames of a building that sits across from a park, and that same pine could match the indoor flooring and framing, so the indoor and outdoor surfaces match and tie directly into the outdoor environment.

Fun Fact

The Eastside Machine Co. EM 6/8/10 Combo Seamless Siding Machine was used to manufacture the world’s longest continuous piece of seamless steel siding in 1998. This accomplishment earned it a spot in the Guinness Book of World Records. The siding measured 236 feet 9 inches long and was installed on a commercial building in Fargo, North Dakota, by a United States Seamless dealer. The record still stands today.