Atlas Bolt & Screw

Atlas Bolt & Screw supplies metal-to-wood and metal-to-metal fasteners.

For best practices, they recommend:

• The majority of construction fasteners are made of hardened carbon steel. For industrial or coastal applications where corrosion would be a concern, the choices would include zinc-headed fasteners or stainless steel.

• Use the appropriate fastener as specified by the panel supplier or engineer. The fasteners are generally a tiny percentage of a building’s cost. The correct length, material, quantity and fastener placement will ensure a long-lasting installation.

• Use the proper tools for installation. A screw gun with adjustable torque settings is a good choice.

• Keep the nut-setter magnet free of metal chips so as not to scratch the painted heads.

• Do not leave fasteners in plastic bags in wet environments on the jobsite while waiting to be installed.

Again, use the correct fasteners and follow the panel supplier’s recommendations on their placement; many of these panel designs have been tested and have code approvals.

BECK America

Addressing fasteners used in post-frame installation, Brett McCutcheon of BECK America (a BECK member) recommends using their wood-to-wood patented diamond coated jumbo nails. (The Jumbo Nailing System consists of 4- to 6-1/8-inch pole barn nails and a jumbo nailer.) Additional fasteners recommended are metal-to-wood nails for attaching metal roofing, siding, and interior liner panels, and special pins for attaching wood to 10- to 20-gauge steel.

BECK fasteners are made of 1082 steel, F1667 compliant and code-approved ESR-1539, true hot-dipped galvanized, 304 and 316 stainless-steel as well as EG and bright.

Before You Start

Factors to consider other than price when selecting fasteners are withdrawal, pull-through, coating quality, coating thickness, drivability, bend yield, tool compatibility and uniformity within spec ASTM-F1667 [Standard Specification for Driven Fasteners: Nails, Spikes, and Staples].

Tips and Tricks

• Don’t forget, not all fasteners and tools used are the same.

• Do know that in post-frame construction in the past few years that looking for new, innovative ways to build can strengthen your business.

• Do recognize there has never been a better time than now to consider alternatives in the space of post-frame construction fasteners.

Dynamic Fastener

Dynamic Fastener supplies builders with metal-to-wood, wood-to-wood and metal-to-metal screws with a long-lasting, premium coating. (All Dynamic Fastener screws are available with Dyna-Coat®, a 1000-hour, long-life premium coating.)

Before You Start

Questions you should ask before purchasing for a post-frame building:

• What is the material I’m fastening?

• Is the project in a highly corrosive environment where a long-life-coated screw would need to be replaced by a stainless-steel screw?

Fasteners in any metal building project is such a small percentage of the contractor’s spending cost, but it’s also an important element to the project. If the wrong fasteners are purchased and installed it will potentially cause problems for the installer, which ultimately could lead to costly repairs.

Tips and Tricks

Avoid using an impact driver to install self-drilling screws. An impact driver can easily shear off the head of the screw during installation. An over-torqued screw head could create excessive stress on the screw. This stress can fatigue the fastener over time resulting in potential fastener failure.

Corded and battery-operated screw guns are available to handle just about any metal that needs to be fastened. It is critical that a torque adjustment system be used to allow you to “dial” the proper torque needed to efficiently drive fasteners without stripping or breaking the fasteners.

Maze Nails

Maze Nails manufactures wood-to-wood fasteners. Regarding fastener composition, it is very important that stiff-stock and oil-quenched hardened nails comply with the ASTM Standard Specification F1667 for post-frame nails. Maze Nails meets and exceeds all these specifications. Adding a ring or spiral shank to the nail will also increase the holding power in posts, trusses and timbers.

Quality Counts

Choose nails made consistently from high-quality steel.

Tips and Tricks

Make sure you read the labels. All fasteners are not created equal. Double hot-dipped galvanized fasteners are not the same as electro- or mechanically galvanized nails. Specifications are key when choosing the right fastener.

Don’t buy strictly on price, but you do get what you pay for. If you don’t want callbacks, do the research on the front end so you can complete your project with confidence.

Other fastener information builders should know for post-frame installation:

• Know when you need a galvanized, hardened, or ring shank fastener when deciding on a nail.

• When coming in close ground contact or when a nail is exposed to the environment, you should use a hot-dipped galvanized fastener.

• When driving longer nails, it is wise to purchase hardened nails to avoid bending issues.

• Ring or spiral shanks hold well and greatly assist in preventing racking of nailed truss and post members.

Triangle Fastener Corporation

Triangle Fastener supplies fasteners to attach metal-to-wood, wood-to-wood and metal-to-metal in post-frame projects. Joe Stager, vice president of Triangle Fastener Corp., shared further advice and tips:

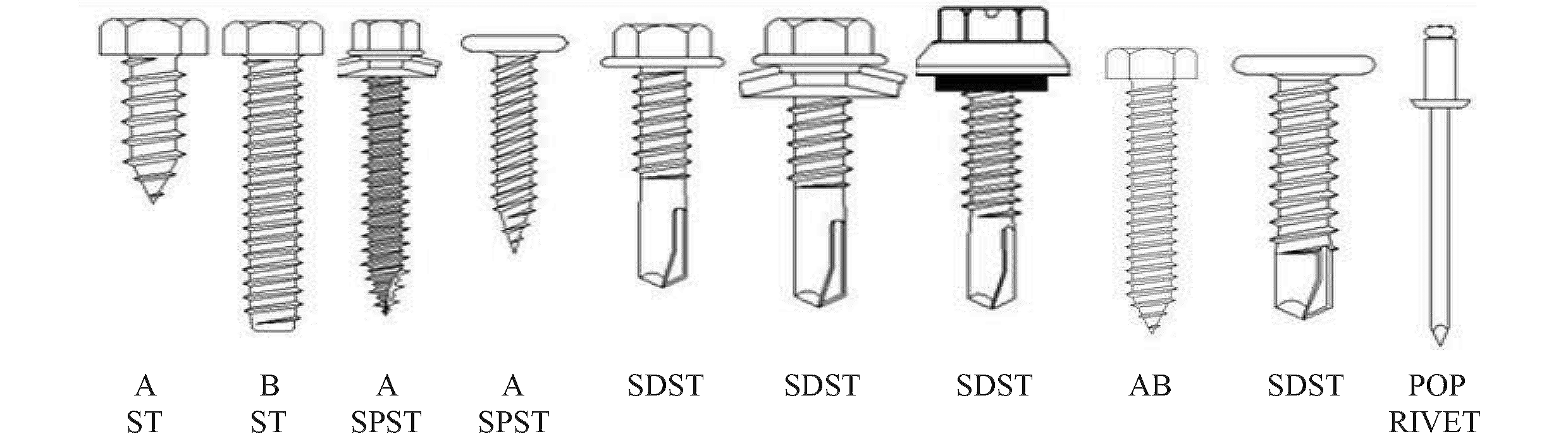

Screws used to attach metal to wood or metal to metal are produced from low- carbon steel or stainless-steel. The carbon steel (C1018-1022) screws must be case hardened in order to be able to pierce steel panels. Screws exposed to the weather and made of carbon steel should have a thicker plating or coating to resist corrosion and should meet a minimum of 500 hours of salt spray per ASTM B117. Carbon steel screws are also available with zinc heads or stainless-steel heads for more corrosion resistance.

These types of screws are also available in stainless-steel. They are made of either 410 grade (martensitic) that is case hardened or a 304 grade (austenitic / 18-8). The 304 stainless-steel grade provides the best corrosion resistance, especially in treated wood applications. It is recommended that screws made of stainless-steel be plated or coated to provide lubricity to the threads for better tapping.

Before You Start

There are many factors to consider when choosing the right screw for your applications:

• Corrosion Resistance: Will the screw provide similar corrosion resistance as the panel and, will it withstand the environment?

• Strength: Will the screw meet the load requirements of connection?

• Will the screw provide the installer easy and consistent installation?

Tips and Tricks

Do: Install screws using screw guns with a depth-sensing or torque control feature to eliminate over-driving or under-driving the screw.

Do: Install the screw perpendicular to the panel.

Do: Screws with an EPDM sealing washer should be tightened so the EPDM extrudes just beyond the metal washer or the flange head of the screw.

Do: Use the correct nut-setter or drive bits to minimize chipping of a painted screw and to improve drivability.

Don’t: Over-drive or under-drive screws. This can cause the screw to back-out and roofs to leak.

Fasteners are a small percentage of the overall cost of a metal roof or wall system, but they play an important role in how the panels perform. Use screws that provide the best overall performance to help eliminate unnecessary callbacks and warranty issues. FBN