Why Proper Ventilation Is So Crucial (and How to Achieve It)

By Bret Buelo, Wick Buildings, Inc.

For a post-frame building to function properly, it needs to be more than just a building. It should be a complete system that’s engineered and built to help ensure good indoor air quality.

This is a critical factor for the well-being of the building itself, as well as all the things that go inside it — from vehicles and equipment, to livestock and horses, to your customer and their guests.

Taking steps to ensure good air quality in a post-frame building will, for example, keep it cooler on hot days, prevent moisture from dripping on your customer and their things, and help your customer stay safer and more comfortable when they’re in it.

So how can you achieve good indoor air quality? It all comes down to controlling the airflow with proper ventilation. Learn about the essentials for proper ventilation and explore what ventilation system may be right for your customer’s building.

Ventilation 101: Outflow and Inflow

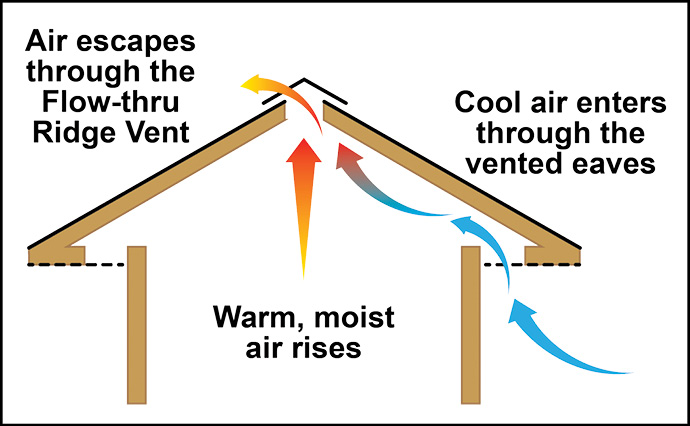

Let’s take a look at how proper ventilation works by examining a basic passive ventilation system.

Vented ridges: Out with the moist, stale air

Cut-away view of ridge vent configuration. Note the venting gap in the peak of the roof, the media that prevents rain, snow and debris from entering, and the cover. Photo courtesy Wick Buildings

The process starts with warm, moist air rising inside a post-frame building. (In the case of a lined building with a ceiling, air is rising in the building’s attic.)

As the diagram above shows, thermal convection, which is basically the movement of heat through fluid motion, causes the air to escape through a ridge vent. (Wick provides our customers with a cost-effective flow-thru ridge vent as standard, with a variety of options should the building require more ventilation.)

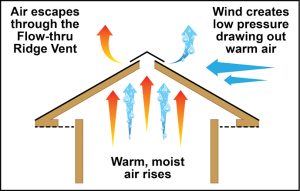

In addition, wind hitting the roof can actually aid this process by creating low pressure, which further draws out the warm air through the ridge vent.

Vented eaves: In with the cooler, fresh air

When that warm, higher humidity air escapes through the ridge vent, it creates negative air pressure inside the building.

And that’s when vented eaves come into play.

Vented eaves are the yin to a vented ridge’s yang. They enable the negative air pressure to draw in cooler, lower humidity air from outdoors. (Other openings, such as doors and windows, can facilitate the process.)

Voilà: That’s post-frame building ventilation in a nutshell.

Finding the sweet spot for outflow and inflow

Not surprisingly, one-size-fits-all ventilation isn’t the best solution. For the most effective ventilation performance, you want to strike a balance between the outflow and inflow of air. And that requires careful consideration.

You will want to make sure the building has the right ventilation for the type of building your customer is erecting — and for what’s inside it. An engineer should be able to calculate what the building needs in order to achieve optimal inflow and outflow.

When Is more than a conventional passive system needed?

Wind hitting the roof can aid in the ventilation process. Photo courtesy of Wick Buildings.

The basic system described above can work great for many types of sheds and post-frame buildings. There are, however, scenarios where your customer may need more ventilation. Here are some common examples:

Curing new concrete. New concrete will release moisture during the curing period. A general rule of thumb is that it takes one to two months of drying time per inch of concrete pad, depending on humidity levels and temperature.

Washing equipment. Frequently washing equipment or vehicles inside a post-frame building will add moisture to the air and create a need for more ventilation. Concrete is porous and will retain water, even if the building has floor drains and the doors are open while your customer is washing.

Storing materials that off-gas. If your customer stores chemicals like fertilizer or other off-gassing substances in an enclosed building, the building will need increased ventilation.

Using chemicals inside. Using spray paint, high-strength cleaning materials, or other strong chemicals demands a high-ventilation environment.

Housing animals. When large animals like livestock and horses breathe, sweat, and generate waste, your customer’s building is going to have higher levels of moisture and odor and thus a greater need for more ventilation to improve air quality.

Using as a living space. If your customer plans to work or live — or just spend a lot of time — in their post-frame building, your customer will need additional ventilation. In fact, commercial and residential building codes specify the amount of “air turns” needed in a human-occupied space to ensure adequate air quality for maintaining good health.

What options are available for greater ventilation?

If your customer does need more ventilation, there are a number of possibilities, ranging from higher volume passive ventilation options to various powered ventilation systems.

Passive ventilation options

Open ridges. These are used with higher density livestock housing and maximize the passive air flow through the ridge area. However, Mother Nature will send rain and snow through the open ridge, so make sure the building is designed properly.

RV-35 and RV-100 ridge vents. These industry-standard higher profile passive vents provide a larger volume of air flow through the ridge, yet still provide weather protection.

Vented cupolas. A vented cupola sits on top of a roof ridge and can be used in conjunction with other ridge venting systems.

Gable vents. These are located high on the gable wall in the attic area, ideally on both ends of your customer’s building, to allow air to flow in and out of the building.

Powered ventilation options

Attic fans or ventilators. Mounted either in a gable wall with opening and closing shutters, or under a covered vent in the roof, they can move a lot of air and can be triggered by temperature or humidity levels.

Power vented cupolas. These electric fans mount in the cupola and can also be triggered by temperature or humidity levels.

Exhaust fans. Similar to the common bathroom fan, these can be used to remove moisture, vapor, or odors from interior spaces or rooms under the attic. Use the appropriate filtering system for the type of exhaust being removed.

Air exchangers. This option is commonly used in residential and commercial environments when the HVAC system is exchanging interior air that is heated or cooled with fresh outside air.

When moist air meets a cold roof: A special note on condensation

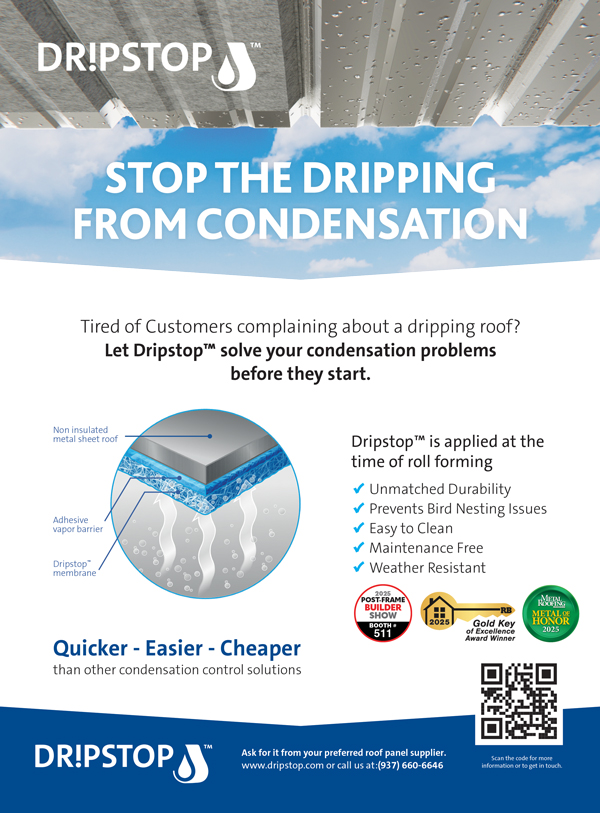

When temperature and humidity conditions reach the dew point, moisture condenses on the underside of a non-insulated metal roof. And when there’s a lot of condensation, drops of water form and start to fall, potentially damaging whatever contents lie below.

The traditional method for combating condensation is to insulate the roof so that the temperature on the inside roof panel never reaches the dew point.

However, there are simpler, more economical solutions. If your customer doesn’t plan on insulating the entire building, you’ll want to consider installing some type of condensation control system on the underside of the roof.

For example, Wick Buildings offers the DRIPSTOP™ Condensation Control membrane, which arrives at our customer’s building site already in place and installed with the roofing panels. (The membrane is self-adhering and is applied to the panels in the roll forming phase.)

Proper ventilation means peace of mind

If your customer needs a post-frame building or shed in the first place, then your customer needs good ventilation. No matter what goes in — and what goes on — in your customer’s building, the fundamentals of proper ventilation should apply.

Be sure you identify up front all the ways your customer will be using the building. Then plan accordingly for the appropriate ventilation system. Ultimately, when your customer’s building can breathe easier, so will your customer and so will you. FBN