SmartBuild Systems shows how well it works.

Sometimes you don’t have to think about what problems people in a specific market may have that you could fix, and then try to sell the solution to them; sometimes they tell you what they want. That’s how Keymark Enterprises got started on SmartBuild. They had developed an integrated steel truss system that started with planning software that enhanced efficiency for customers in their roofing projects. People in the post-frame industry saw it and decided they needed something like that for their industry.

When Keith Dietzen, CEO investigated the industry, he found that some companies had basic software for post-frame that allowed limited configurations; it was a niche that could stand some expansion.

In 2017, a team of five got started learning all about post-frame building, talking to builders, and looking for a solution that would provide more building options and save builders time and money. They began coding software for the post-frame industry, and over two years of development time, they met regularly with prospective clients, received feedback, and used that feedback to improve the software. In 2019, they began licensing clients to use the system.

Business Opportunities

Dietzen said, “SmartBuild was not hard to sell. The amazing thing is that after the major recession we had, the business climate was pretty much recovered in 2017. In the post-frame industry, most companies said they had a backlog.”

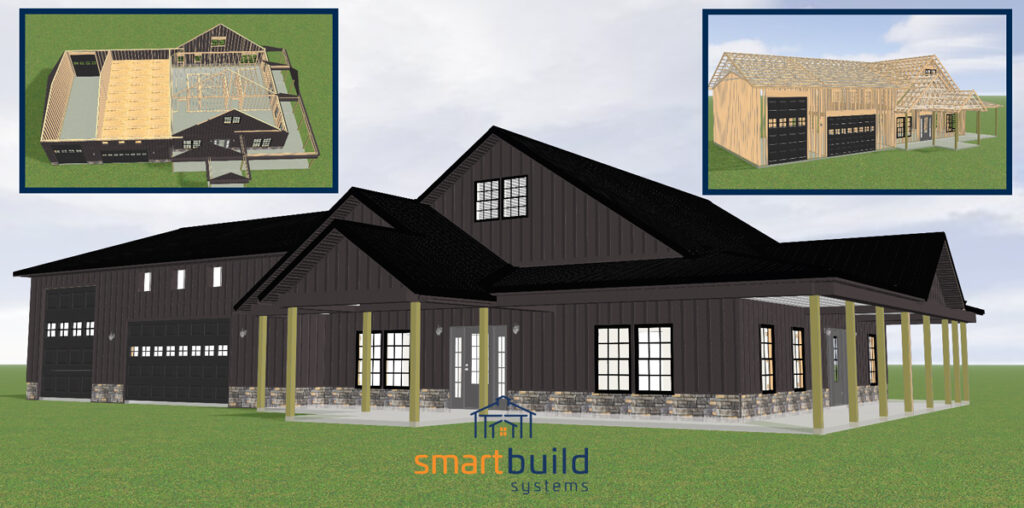

Salesmen used to talk to a customer about what they wanted and then spend 3 ½ to 4 hours creating the representation (or having it created), then calling the customer days later to present their building design. With our new software, they could create a 60’ x 120’ space, 2 levels with three offices and storage in a live 3D design session through a link to the site. It could be done in 15 minutes with a full take-off. If the customer wanted a change, that was a few more minutes. With this software, companies saw sales rise dramatically. While previously they closed on one of every 6-7 bids, with the new software, they were closing half the proposals they ran. Errors went down, too.

Brendon Studholme, Shaun Mandish, and Royden Wagler

SmartBuild plans

Keith Deitzen, CEO, doing business at a trade show.

Along with Opportunity Comes Challenge

One of the features of the software is that a license holder, such as a supplier, can integrate their own inventory into the program, so when contractors login, they can count on receiving the supplies they are used to working with. Of course, some of the greatest improvements bring challenges with them. It takes time to get an inventory number system set up along with building rules, which will specify things like this fastener goes with that panel, etc. People are hesitant to take the time for setup, though the company provides someone to help set it up, train them and make sure it is up and running for them. Another incentive to entice customers to take the time to set up and become conversant with the system, is the knowledge that, once it’s done, there is very little maintenance, and the software can be made available to contractors. This program can help engender lasting loyalty to the supplier, since it makes the contractor’s life easier. They rarely go elsewhere once they’ve used this system.

Growth

In the last couple years, the company has seen a lot of growth. This is, Dietzen said, in part because the post-frame industry is so strong. He didn’t see much pull-back in demand in the post-frame market during the COVID-19 quarantines, nor is he seeing it today, though interest rates have risen to around 8%. Dietzen said that for at least the past two years they have attracted 25-30 new customers every month. The newest spur to growth is the demand for barndominiums, he said. These combined storage/work/living spaces are continually evolving and requiring greater and greater sophistication on the part of the builder. The whole industry is benefitting from the demand.

“I hear every day that barndos are bringing lots of business and they continue to fuel the economy for the post-frame market,” Dietzen said.

Another factor in their growth is, Dietzen believes, that they are offering the first software for this market that is devoted to continuous improvement. Now, with 12-18 software developers, they are doing software updates every 4 to 6 weeks.

Employees Matter

The culture is one of listening to and focusing on the customer. The company has a daily stand-up meeting with lots of sharp minds engaged in lively brainstorming, spirited debate, and lots of energy focused on software change requests from their customers. Every day they look at what progress they have made and what takes priority for the next update, which traditionally consists of 25 improvements including small tweaks and larger changes too.

All these changes require every member of the team to be on board, and Dietzen acknowledges that businesses work better with happy employees. That is why they screen job candidates, not only for hard skills, but also for certain traits. They look for focused, goal-oriented people who have no hidden agenda. Every prospective hire interviews individually with the others on the team to ensure the chemistry is right. This seems to have paid off; Dietzen said that no one has left, not the original team or new hires.

In Retrospect

Dietzen said that if he went back to the beginning of SmartBuild, he could have focused more on a sales strategy; they have a website to get out the word, and they attend trade shows, but they have never gone out in the field to sell this software. Who knows how much bigger the company might be if they had? On the other hand, he said, the seven years in business have been very successful. He attributes this to taking the time to listen to the market, taking the time and money to invest in development, and hiring experienced, quality people to create a web-based application that didn’t exist before.

Moving On

More recently the company partnered with Sherwin-Williams, EagleView, and RoofingWRX to create Roofing Passport, which helps builders with metal roofing takeoffs, so a contractor’s whole building planning process can be simplified. Dietzen said this was another innovation based on a request from a member of an adjacent industry.

Dietzen believes that his company will continue in the same vein, listening to customers and others and going where that takes them. He sees opportunity in the all-metal building world, so stay tuned for developments on that front.

Dietzen would like to thank the customers, those who were with them from the start and others who have joined them along the way. He would also like to thank his employees because, as he said, “Teamwork is mission critical. We couldn’t do it without you.” FBN